Experts weigh in on small footprint car wash opportunities

There is little doubt among car wash operators about which type of system brings in the most revenue. Tunnel washes deliver a faster clean, offer more add ons, and provide more vehicle volume than any other type of equipment. More cars mean more sales and profits.

However, not every site is ideal for a 120-foot tunnel. This difference is where in-bay rollover and mini express systems shine. These systems can squeeze into a 40-foot commercial space for a lot less upfront cost. Consider that a full-scale tunnel operation can run close to $1 million (without land costs), while a compact in-bay rollover might be $300,000.

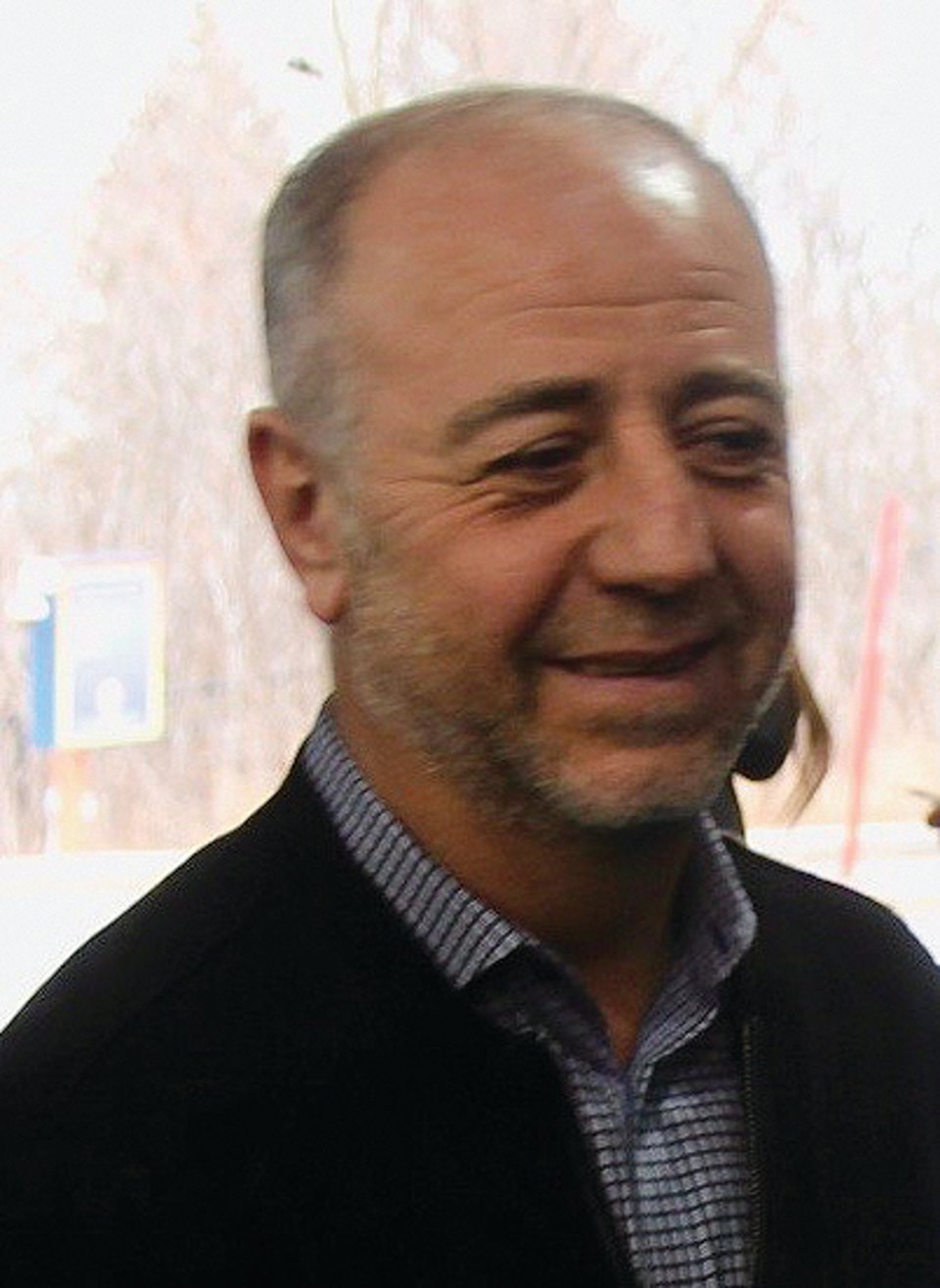

President Nex Consulting and VP operations at Burlington-based Auto Spa, Fred Misheal, suggests in-bay cannot compete on time or quality with tunnel washes. "But, they are convenient and provide a good side revenue for operators. With in-bay systems, time is the major factor. While a tunnel wash can move customers quickly from the line-up to inside to finish, an in-bay unit runs about four minutes per car. This slower speed means a line of four or five cars can create a 20-minute sitting period with customers getting impatient. Also, the quality in a rollover is often less than in a tunnel where customers can choose from a wider variety of add- ons. In-bays reflect a compromise that has to be made when there is not enough room for a tunnel or enough investment capital,” he says. "In-bay systems are ideal for car dealerships, auto body shops, and car rental operations as well as small footprint gas bars where space is limited.

“There is still good money to be made on in-bay rollover, despite the fact volume is less than a tunnel," adds Misheal. "Once the system is in place and running smoothly, operators just need to spend on soap, water and utilities leaving a large portion of the price of wash available as profit."

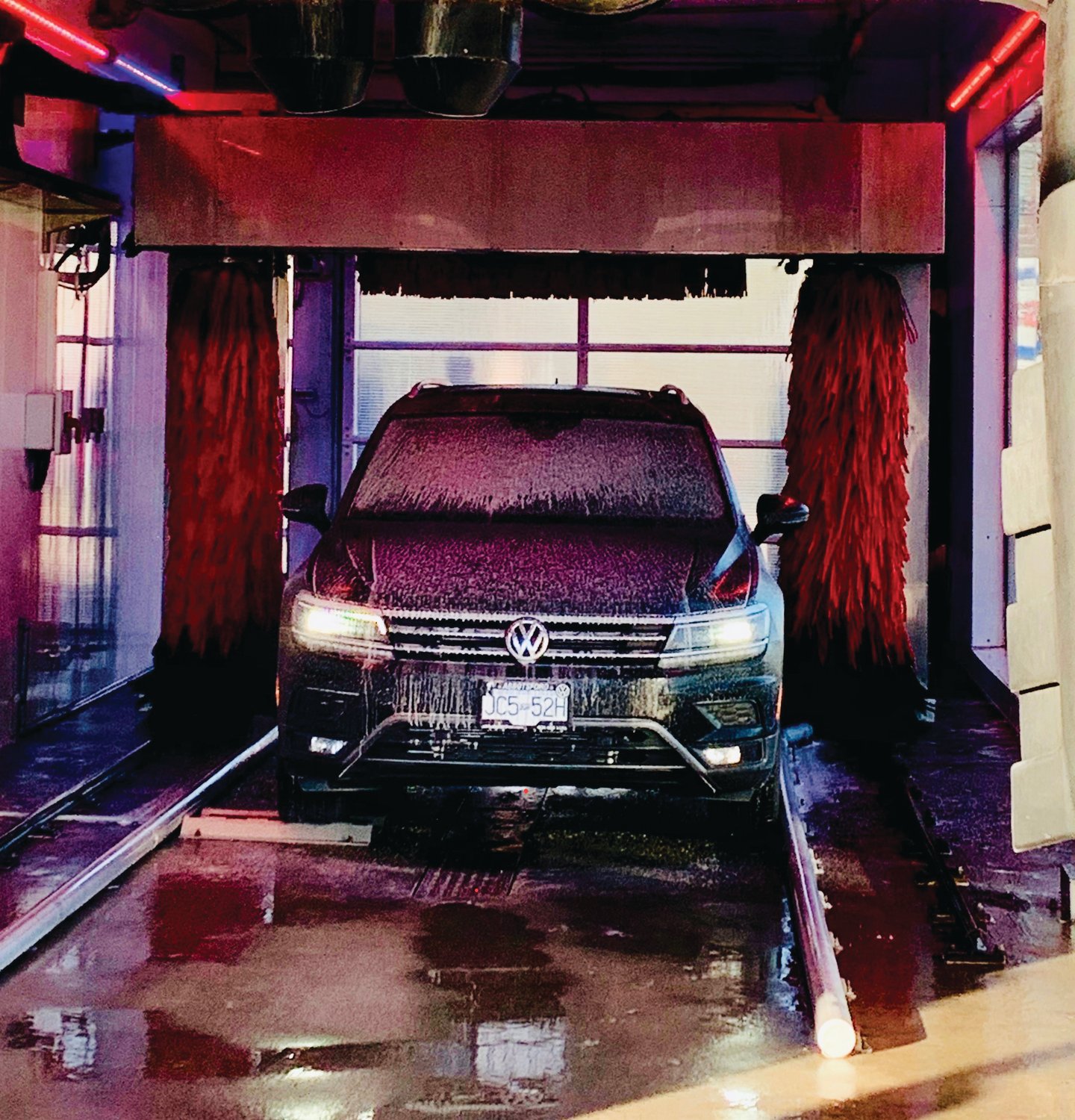

Operators such as Shell, Circle K and 7-Eleven Canada have utilized the benefits of in-bay at locations across the country. Circle K moved away from touch-less operations last year looking at soft touch friction systems at its sites, while 7-Eleven Canada offers both soft-touch technology and touch-less options. This ability to provide choice has proven to be a good fit for 7-Eleven Canada as it expands its wash packages to more locations where in-bay is viewed as a perfect fit for the chain, given its typical placement in high population areas where space is at a premium. 7-Eleven locations utilize systems from Ryko and MarkVII.

At the 2020 CARWACS event in Abottsford, B.C., attendees toured a nearby 7-Eleven Canada site with a Choice XT wash system. The Choice XT offers both touchless and soft-touch options. At the time, customers at this site used the top wash selection most often with vehicles coming through with a hand-polished look. Customers still are attracted by LED lighting that shines through a full-length window wall helping to deliver above-average monthly throughput at this single in-bay location.

“The industry has seen a change in the in-bay area,” says Jamie Shaw, national car wash manager Canada, 7-Eleven Canada, Inc., “Customers used to seek out touchless systems because of concerns about paint scratches. Now, with new brush technology, there is no need for worry. One of our sites in an upscale Vancouver neighbourhood attracts a range of drivers using the soft-touch in-bay.”

Equipment innovation moves in-bay forward

With rollover systems moving away from touchless systems, non-scratch brush technology is now more important. Here, Gallop Brush Co offers GFlex Foam, a brush that is gentle on car exteriors, buffs and shines the vehicle while cleaning and keeping noise to a minimum. NonFade Cloth is another improvement that is more durable than foam and can deliver a more aggressive approach to cleaning.

Gallop Brush Co.'s innovation also helps operators maintain brushes for the best performance. For example, Gallop’s Core and Core Guard work to stop core erosion and extend the life of this important equipment system. “This gives the customer a cost and time savings,” says Michael Yamin, director of operations, Gallop Brush Co. “Now operators will not need to replace their core as often saving them money which leads to a time savings because a maintenance crew will not need to shut the wash down to replace equipment.”

At MacNeil (NCS) they offer an in-bay Express Mini Tunnel to capture the best of both worlds. The LT In Bay Express Mini Tunnel works in spaces as small as 35-feet long by 16-feet wide, and the company suggests the system can convey 50 cars per hour, a big step up from in-bay rollover equipment where operators see volumes around 15 cars per hour.

Sonny’s is another leading manufacturer with options for both in-bay rollover and mini tunnels. The 43XTB can wash, wax, seal, tire shine and dry up to 50 cars per hour from a 35-foot bay. Included in this chain pull system is a Mr. Foamer, fully-lit Pinnacle Arch, electric 2K14 Top Brush with NEOGLIDE Hush, and a Banana Hybrid Kit for Tri-Foam with LED Light. There is also a 10-foot Rain Multi-Arch with three manifolds in addition to a Foaminator Maxx Stream with LED Light for Wax Application. At the back, dryers deliver lots of air plus added zing with LED Lights for Toaster Effect.

Belanger suggests its Freestyler in-bay rollover system rivals a 100-foot tunnel for quality. Freestyler is quicker than most in-bay rollover systems with a 20 car per hour throughput. Freestyler uses an overhead gantry and five brush system to clean cars. Available is a hydroblading system with ten high-pressure nozzles to get dirt from crevices and hard-to-reach spots. There is also a wheel cleaning system that uses 15 high-pressure nozzles per side.